CBR600RR

Select CBR600RR year below to see compatible parts.

2024

Racing Kit Parts

The HRC Racing Kit is a race-only kit to enhance the performance of the CBR1000RR-R on race circuits, targeting a wide range of users. Racing kit parts compliant with regulations of each country are available.

When incorporated with the HRC Racing Kit parts below, the CBR600RR race base motorcycle can comply with the stock regulations and transform into a competitive racing machine in the Supersport Next Generation class.

Main changes in the 2024YM

- Stability during braking improved further by damping characteristics of the front suspension and air counterforce characteristics.

- Throttle operation linearity improved by redefining a map profile of the power mode, and addition of the throttle grip adjustment control in the FI data setting.

- Stability during turning and traction during acceleration improved more than the existing models by introduction of the ignition cut control at the exit of corners.

- Improved output in the entire range of mid- to high- RPMs with newly prescribed spark plugs.

PGM FI UNIT

- In addition to major update of racing control from the previous model, the additional new control function allows fine adjustments of machine settings to improve performance on the circuit significantly.

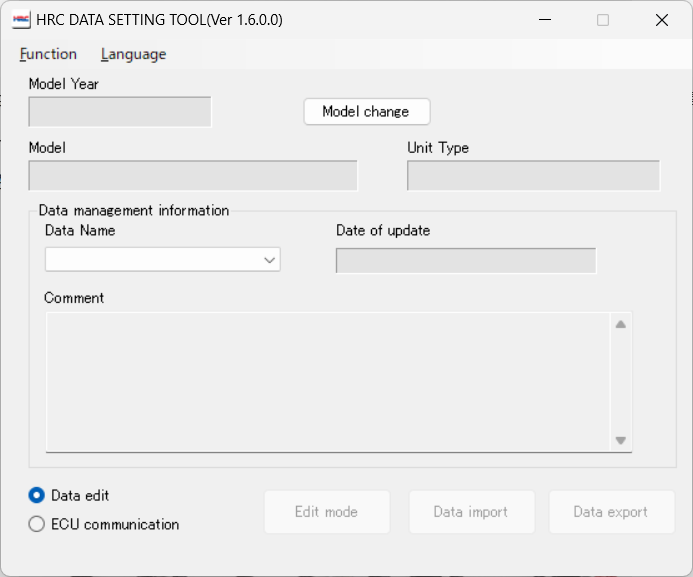

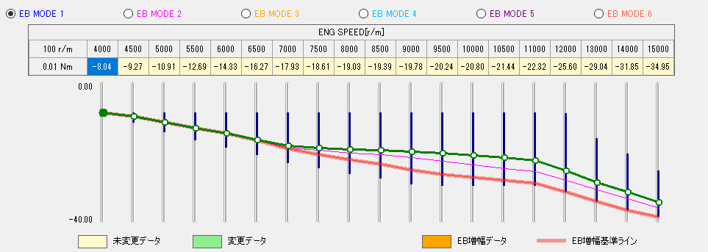

Data Setting Tools

Power characteristic map profile and opening settings have been redefined to further improve maneuverability for exiting corners. In conjunction with the TH Grip Adj, this feature allows modification of output characteristics in response to grip operations.

【HRC_DataSettingTool_v162.zip:122MB】

- September 2024 Version 162 Update: Kvaser V3 Compatible

The HRC Setting Tool manual is available for download from Motopub.

https://www.hondamotopub.com/HRCE

SPARK PLUG

- The spark plugs improve output by 0.4% and drivability throughout the RPM range over 6000 RPM compared to ones fitted as standard.

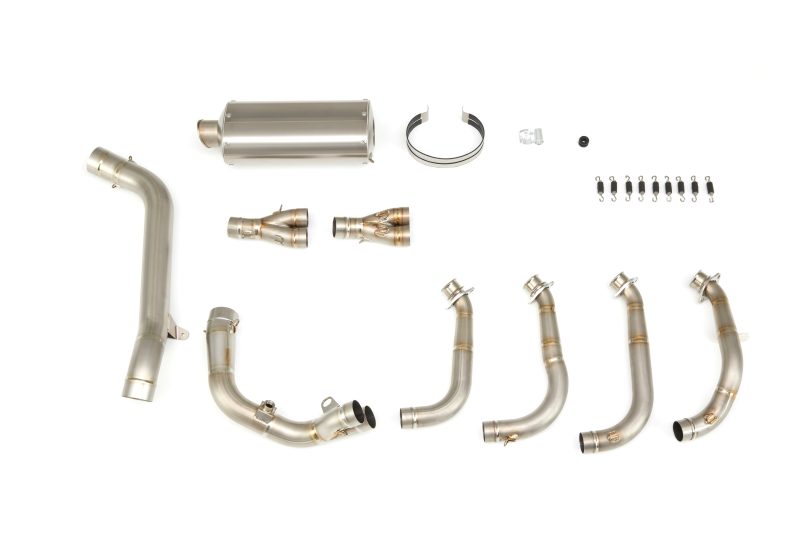

EXHAUST SET

- The exhaust set is entirely made of titanium, contributing to weight reduction.

Optimized pipe diameters and lengths achieve maneuverable output characteristics from low-to high-speed ranges.

CLUTCH SPRING

- The spring material was changed from the one used for mass production springs to improve toughness at the time of starting at a high RPM and with high load.

RADIATOR

- The large radiator optimizes water and oil temperatures to cope with increase in engine heating during races.

- Proportion of the core of the component radiator was increased by 10% compared to the one for mass production, so that heat dissipation can be improved by up to 5%.

- Some water hoses and the lower stay were newly prescribed along with size increase of the radiator. (Water pump hose to be selected according to the type of stroke sensor.)

- When the oil cooler outlet hose is connected to the radiator to let the heated water go through the radiator, cooling efficiency is improved.

- Orientation of filler neck installation is reversed to optimize routing of the tube connected to the catch tank.

SW UNIT, ST ENG STOP/SW ASSY., WINKER

Throttle Set (APS unit and ENG STOP switch)

When used in combination with the throttle pipe (53140-MKR-D31) for the CBR1000RR-R, this set turns the model into a high throttle type compared to the mass production design (74 degree to 65 degree) to achieve larger throttle angles by turning the throttle less.

Expected benefits include quicker operations to the full throttle and better operability in a forward-leaning posture.

Turn signal switch

Various switches can be used to operate the color LCD meter.

Additionally, racing functions can be activated/deactivated immediately while riding by operating the turn signal switch and LAP switch.

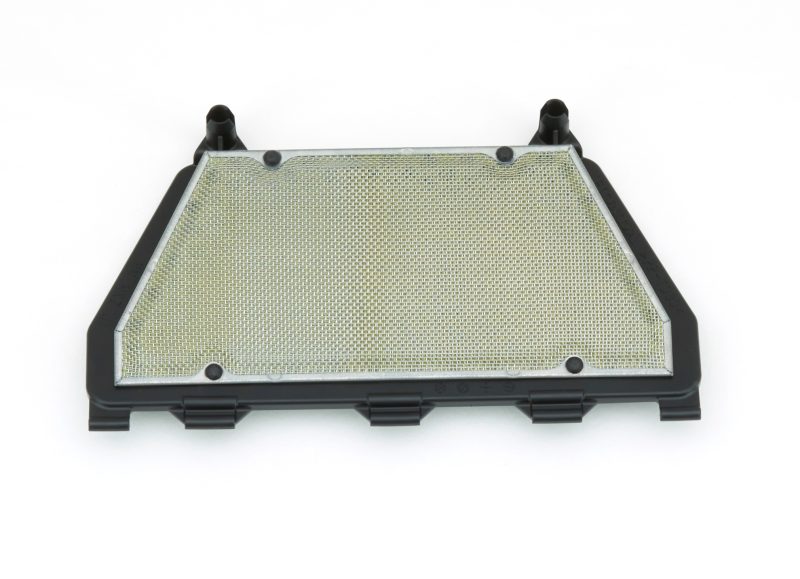

AIR CLAENER ELEMENT

Compared to the mass production model design, the race-only element frame is no longer fitted with a filter element in order to reduce air intake resistance and improve intake efficiency.

FORK ASSY., R. FRONT / FORK ASSY., L. FRONT

- The front fork in the racing kit has settings more specialized for riding on the circuit, compared to ones for mass production model.

- Settings of the previous model have been changed for the 2024YM to further improve stability during braking.

- Three types of springs with different spring rates are available as options.

- The front fork in the racing kit has higher damping force settings to be more specialized for riding on the circuit, compared to ones for mass production model.

RR. CUSH ASSY

- The piston is larger in size than the one for the mass production model to improve damping responsiveness.

- The spring rate for the rear cushion in the racing kit is softer than one for the mass production model.(Harder design for the mass production model taking pillion riding into consideration.) Furthermore, five types of optional springs are available.

- The preload adjuster style was changed from the multi-step cam used for the mass production model to the separate knob for easier and finer adjustments.

- The damping force adjustment mechanism allows individual settings for high and low piston speeds on the compression side

- The screw-type length adjustment mechanism has been added to the bottom of the main body. Aside from the preload adjustment, longitudinal tilts of the vehicle can be adjusted.

*The rear fender needs modification for installing this mechanism.

DAMPER ASSY., STRG

- When the main harness and the PGM-FI unit from the racing kit are used along with the electronic steering damper of the mass production model, damping force will stay at its weakest. Use of this mechanically adjustable steering damper or an off-the-shelf damper is recommended.

- The damping force of the mechanically adjustable steering damper is set by default to be suitable for riding the CBR600RR on the circuit.

- Damping force is adjustable by turning the screw adjuster with a flat-head screwdriver.

- Damping force is adjustable without removing the top shelter (a cover on top of the tank), when a hole is machined in the top shelter at the position where the steering damper adjuster comes below.

BRAKE PARTS

- The brake parts in the racing kit were developed for reducing performance deviations associated with heat generation, and improving controllability.

- The piston material of the front brake caliper in the racing kit has been changed from aluminum to iron that was used for the mass production model. Moreover, the geometry of the pad shim assembled in the back of the brake pad has been changed. These changes have reduced variance in free play of the brake lever in response to temperature fluctuations around the brake caliper to ensure controllability in the thermal limit region.

- The plate thickness of the front brake disc in the racing kit has been changed (from t4.5 to t5) to ensure better thermal toughness than the mass production model. Furthermore, choosing brake feels over noises and vibrations, springs are no longer used and clearance in the axial direction has been designed around the floating pin.

- Brake pads with different characteristics are available as options for both front and rear brakes.

- The SUS mesh hose is prescribed for the front brake hose in the racing kit.

- More expanding hose than the SUS mesh hose is intentionally selected for the rear brake hose in favor of an ease of vehicle posture control.

SNG Racing KIT

- The racing kit mainly comprises engine and electric components for participating in the WSSP and the Supersport Next Generation class held primarily in European countries.

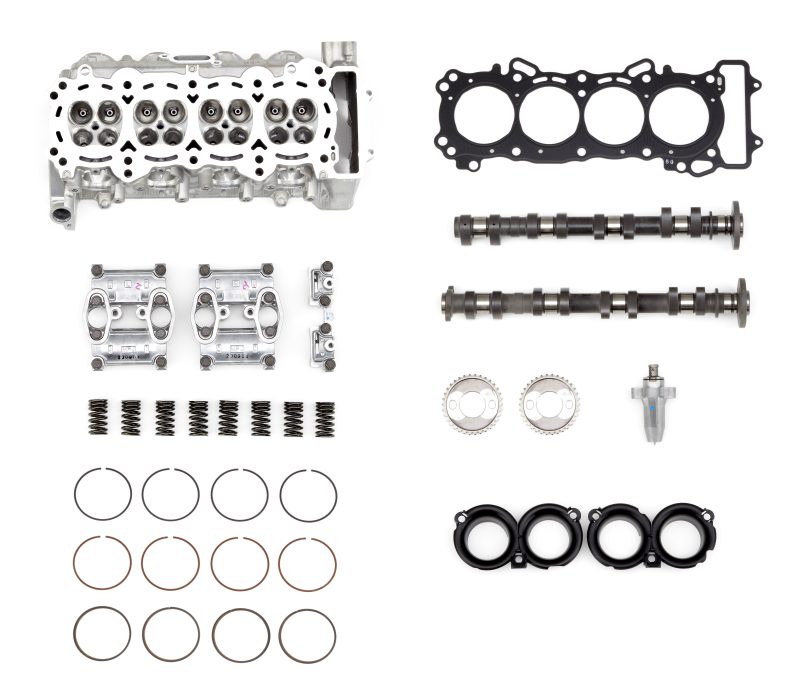

CYLINDER HEAD/CAM SHAFT

・Aiming for high output, combustion chambers and intake/exhaust ports of the cylinder head were additionally machined. Deck surface was milled. Changes made to the camshaft include valve timing and valve lift curve design. Toughness of the intake outer valve spring was improved to respond to the high RPM engine.

・The air funnel has been designed with a shorter pipe than the mass production specification to improve high RPM output.

・Two types of cylinder head gaskets with thicknesses different from the mass production model’s are available.

・The tensioner lifter has been designed with lower pushing force to reduce friction inside the engine.

・Piston rings with the lower limit of the tolerance were selected among genuine parts.

HARNESS, WIRE

・Compliant with the Supersport Next Generation regulations, the harness connects to the common ECU (MecTronik).

・Additional connectors include the safety light connector directly activated from the ECU and various sensor connectors.

STARTING CLUTCH

This part is meant for detecting crank rotational fluctuations.

JOINT COMP A

- This pipe is for cooling water and to be used when the air-cooled oil cooler is adopted. The pipe has been designed without a branch pipe to the water-cooled oil cooler, that was present in the mass production design.

Racing Kit

The 2010 CBR600RR Racing Kit is to be released by HRC in January. These parts are intended for road racing use only.

CBR600RR Racing Kit is intended for wide range of customers to participate in races, as well as improving the competitiveness of the machine with exhaust pipe, silencer, air funnel, clutch, radiator, suspensions, meter, ECU and other parts replaced into race-use-only parts.

Improvement of the performance is intended by variety of engine and chassis parts.

- * Appropriate specification according to each race regulation to be selected for participating in racing.

- HRC racing motorcycles are made for competition use ONLY, and are NOT covered by warranty and NOT to be ridden on public roads.

- All specifications are subject to change without notice.

- Please consult your authorized Honda motorcycle dealers.

- HRC products are not available in all countries. Please check with your local dealer on parts availability and ordering procedure.